Plastic packaging is available in a variety of shapes and sizes. However, not all plastics are created equal. When it comes to food and beverage packaging, it’s critical to understand the various functionalities and uses of common food-grade plastics.

Types of Food-Grade Plastics

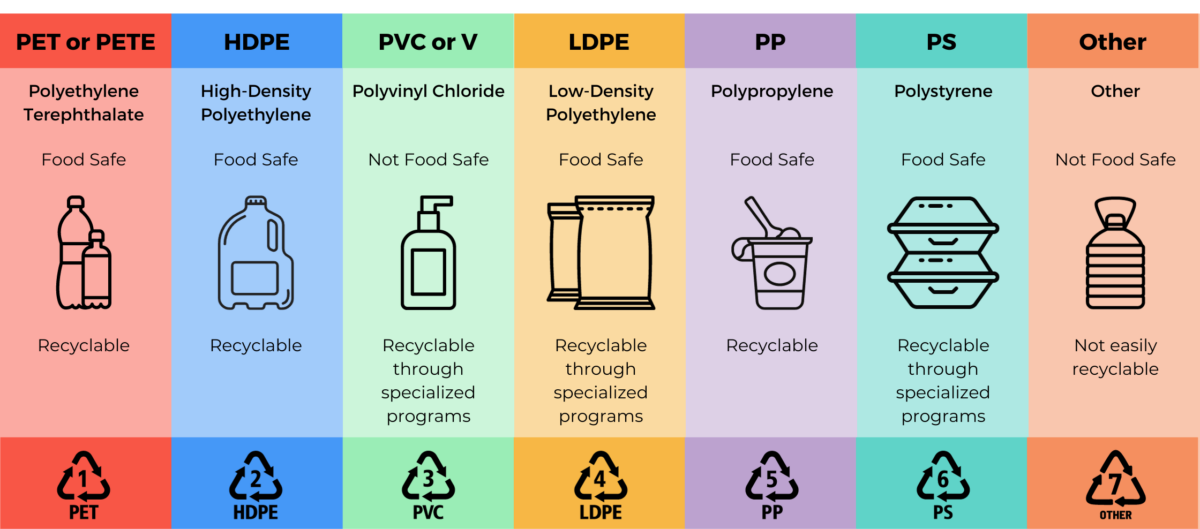

PET or PETE (Polyethylene Terephthalate): Food-safe and recyclable, PET is known for being lightweight, transparent, and resilient. This resin is commonly used to make bottles for carbonated beverages, water, juices, salad dressings, and condiments.

HDPE (High-Density Polyethylene): Food-safe and recyclable, HDPE has a lightweight feel, is extremely durable, and is resistant to acids, making it the ideal resin for packaging such as milk jugs and detergent bottles.

PVC or V (Polyvinyl Chloride): Because of its long-term stability, PVC is frequently used for clear food packaging, such as food trays and wrapping. PVC is not food-safe and is only recyclable through specialized programs.

LDPE (Low-Density Polyethylene): LDPE is food-safe and is less rigid than HDPE. It’s used to make more flexible packaging, such as sandwich bags, bread bags, and sometimes even squeezable bottles. LDPE is recyclable through specialized programs.

PP (Polypropylene): Food-safe and easily recyclable, PP is commonly used as single-serve packaging. PP has a high melting point as well as excellent chemical resistance.

PS (Polystyrene): PS is food-safe and recyclable through specialized programs. PS can be rigid or foamed and is commonly used to make foam takeout containers and plastic utensils.

Other: This category is a catchall for other plastic resins. Items made from these plastics are not considered food-safe and are difficult to recycle but can sometimes be recycled through specialized programs.

Another resin worth noting is polycarbonate. Polycarbonate falls under the Other category and is known for its heat resistance, durability, and being non-reactive. With increased concern about the safety of Bisphenol A (BPA) in polycarbonate plastics, the FDA continues to monitor and regulate the use of BPA-based polycarbonate resins in food containers and packaging. Food-grade polycarbonate is often used to make baby bottles, reusable water bottles, water jugs, and other food storage containers.

Food-Grade vs. Food-Safe Plastics

The Food and Drug Administration (FDA) has approved specific types of plastic resins to be used in the storage and preservation of food and beverage products. Food-grade plastics are manufactured to a higher standard than other plastics and are deemed suitable to come into direct contact with food. However, not all food-grade plastics are approved by the FDA to be food-safe. Food-safe means the finished product made of a food-grade material that is suitable and declared safe to use for the specific purpose for which it is designed. These two classifications are not interchangeable, and the distinction must be considered when following food safety and storage guidelines.

Choosing the Right Packaging

There are several factors to think about when it comes to choosing a food-grade plastic. First, it’s important to take into account the type of food or beverage product you will be packaging and any potential interactions with the plastic resin. For example, acidic foods may interact with certain types of plastic, causing them to break down or leach harmful chemicals into the food.

Another factor to consider is whether you will need to employ a hot-fill or cold-fill process. Some plastics can withstand the extreme temperatures used in these filling processes without melting, distorting, or compromising the product. Heat-set PET is the most commonly used plastic for hot filling because it is designed to withstand hot-fill temperatures while preserving its transparency and lightweight properties. Cold-fill products require multi-layered packaging that utilizes barrier techniques and can be designed to have a blown-in handle. HDPE, PET, and PP are easy to mold, have excellent chemical resistance, and offer thermal stability, making them the ideal plastics for the cold-fill process.

Overall, choosing the right food-grade plastic is critical for ensuring the safety and integrity of your food product while also effectively representing your brand. At Gamer Packaging, our experts are here to guide you through the packaging process and determine the best packaging solutions for your company. Connect with us today to learn more about our extensive selection of stock and custom food packaging solutions and discover how we can help your business grow!

Learn more about our Food Packaging Services and Capabilities!