The humble aluminum beverage can has seen its reputation transformed in the past decade.

From primarily a package for macro light lagers and soda to the go-to package for craft beverage brands around the world. This transformation has presented a problem. There are only a handful of companies that manufacture aluminum cans and supply has always been tight. Add in a Global Pandemic that increased at home drinking and you’re left with a situation where demand for beverage cans is outstripping supply with limited signs of improving anytime soon.

The modern aluminum beverage can trace its origins to 1959 when Coors introduced the first all-aluminum, seamless, two-piece beverage container. Aluminum cans first made inroads into the soft drinking market in 1964 when Royal Crown Cola released its RC Cola and Diet Rite in cans. From here the industry grew, steadily replacing glass as the go-to packaging solution for soda and as a secondary option for many beer companies. Despite the size of the industry, only a handful of companies manufacture aluminum cans due to the large capital expense required.

Fast forward to early the 2000s. Craft beer is booming. Small startup breweries, looking for ways to differentiate their products begin to experiment with something once thought unimaginable, craft beer in cans. Turns out this was a hit. Consumers loved cans and over the next decade it quickly became the go-to packaging solution for craft breweries across the country and around the world. As consumers started to see their favorite craft beer in cans, the rest of the beverage industry took note. As new companies launched selling everything from ready-to-drink cocktails to sparkling water they looked to the success of craft brewers and chose to primarily package their products in cans.

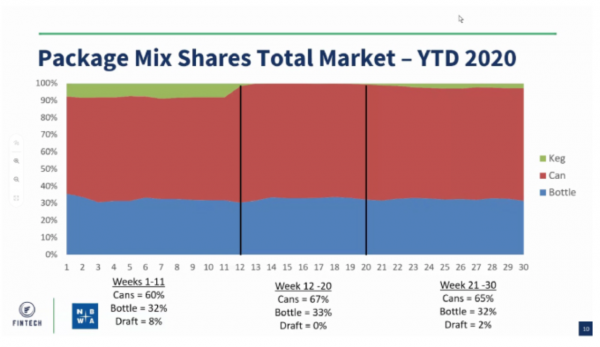

COVID-19’s impact on the beverage industry cannot be overstated. During the time of the pandemic consumer drinking habits have fundamentally shifted. While it remains to be seen if those habit changes are temporary or long-term, the immediate impact of this shift has been felt across the beverage industry. The biggest change due to COVID has been the closure of bars and restaurants. In beer for example, earlier this spring when on-premise establishments were completely shut down for on-site consumption, draft beer — which normally accounts for 8% to 10% all beer sold — saw its share drop to 0%, according to National Beer Wholesalers Association chief economist Lester Jones. Simply put, with nowhere else to-go, consumers are drinking more at home, of everything. This has meant that an already tight aluminum can market now does not have the production capacity to meet demand.

The Brewers Association (BA), the trade group that represents the country’s small and independent brewers, published a can shortage advisory in early August warning members that “demand is likely to continue to outpace supply through next year or possibly longer.” The BA noted that breweries are now competing with wine and spirits producers for cans, as those categories have both begun offering canned versions of their products. Brands today face the existential risk of not being able to source the packaging need to sell their products at retail.

The good news is that the future is bright for the industry. Consumers love the portability and recyclability of cans. New companies specializing in mobile canning have allowed startups beverage companies to package their products and enter the market without spending hundreds of thousands of dollars on a canning machine.

Can manufacturers are working to increase supply and new companies are entering the US market. In late July, a large European can manufacture, CANPACK, announced their first US plant in Olyphant, PA. Opening in December 2021 this plant will add 1 billion cans per year of supply to the US market. The industry will catch-up, the question is how many brands will survive to that point.

What we’re reading

https://www.cnn.com/2020/07/22/business/beer-shortage-aluminum-can/index.html

https://www.businessinsider.com/can-shortage-means-beer-might-be-out-of-stock-report-2020-7

https://www.foodandwine.com/news/can-shortage-drinking-at-home-quarantine

https://www.brewbound.com/news/ska-brewing-sources-old-cans-amid-can-shortage/

https://www.brewbound.com/news/ball-adds-canning-capacity-as-craft-breweries-feel-the-crunch/

https://www.brewersassociation.org/association-news/can-shortage-advisory/

How Gamer Can Help:

Gamer Packaging is no stranger to supply shortages. Over our 30+ years in the beverage industry, we have been through challenges like this before and have helped our clients navigate them successfully. We have strong, decades-long relationships with all major can manufacturers and can secure volume in printed or brite (unprinted) cans for our customers.

If you’re currently experiencing shortages or looking to secure a second source of supply, please reach out to one of our Gamer Packaging representatives today.